Features:

- Non-sediment forming membrane which offers easy cleaning.

- Non-consumable and repairable membrane having a lifespan of >16 years.

- Pro-rated warranties valid up to 2 years.

- Non-permeable membrane prevents common anolyte leakage from getting mixed with e-coat bath.

- Pressurized unit that produces high flow rates and offers enhanced anode cooling.

- Cells having a very low anode consumption level, i.e. around 15%.

- Available in custom lengths

This product supports features that help the automotive industry boost up the production.

Features:

Features:

- Provides zero paint bypass.

- Offers high permeate flow rate of around 1500 LPH per single unit on a clean start-up.

- Reduces bacterial growth inside the system.

- Requires less maintenance due to the presence of disposal vessel.

- Available in packaged rack design.

- Available in rack designs having online CIP and automation.

- Works for 6 years when operated in a right manner.

Features:

- Numerous membrane configurations handle hard water treatment processes.

- Maintains the quality of the tank to lower the drag, dumping, and carryover of contamination.

- Packaged plant comes with full automation.

- Ultra-filtration, nano-filtration as well as reverse osmosis (RO) filtration technologies are available to treat all types of water.

- Total water management feature is also available.

- Bag filters are available to rinse tanks.

- Filters are verified to be silicon-free.

- 3M 100 and 500 series bag filters help in effective oil reduction.

- 3M Duoflo offers high efficiency and around 4 to 6 times longer life than other standard bag filters.

For paint mix filtration, New World Filtration’s 3M Betapure AU is a perfect option.

Features:

Features:

- Lowers the paint defects and nozzle plugging.

- Rigid graded pore structure supports longer lifespan and zero unloadings.

- Designed to effectively maintain the specified pigment sizes.

- Classification filters, perfect for retaining the metals in metallic paints.

- Primary water treatment

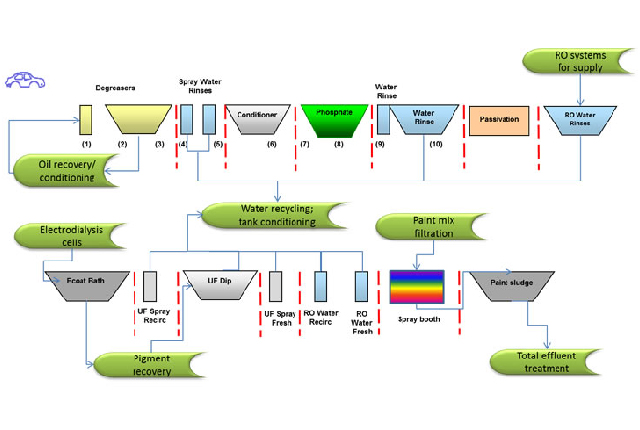

RO and UF Systems:- Packaged RO system feeds clean water to tanks.

- Modifications allow reuse of the rinse tank waters.

- High recovery and high rejection systems are available.

- Fully automated RO and UF systems are also available.

- Stainless steel RO and UF systems offer lower growth of bacteria.

- Secondary water treatment

Rinse and dip tank conditioning:- Multiple membrane configurations available to deal with waters that are difficult to treat.

- Offers total water management feature.

- Maintains the tank quality in order to lower the drag, dumping and carryover of contamination.

- Fully automated packaged plants are also available.

- Supports filtration technologies including nanofiltration, ultrafiltration and reverse osmosis filtration.

For effective oil recovery in the automotive industry, we offer Tubular UF system.

Features:

Features:

- Supports oil concentration around 40% for reuse.

- Maintains degreaser bath oil levels for reduced drag-out or carryover.

- Reduces the risk of tank dumping for downstream and degrease rinse.

- Retains the surfactant and alkaline which is used in degreasing tanks.

- Lowers the water usage downstream.

Features:

- Lowers the footprint over coagulation and flocculation.

- Treats difficult wastewater effectively.

- Offers external as well as submerged MBR model options.

- Lowers waste discharge.

- Recovers water that can be reused in upstream processes.